+61 2 9449 2929

Request a Callback

Request a Callback

OmniCure LX400+

The OmniCure® LX400+ offers ultimate control and repeatability for UV curing manufacturing processes to ensure consistent reliability and highest product quality. Found in the OmniCure® LX400+, our patented Intelli-Lamp® technology allows users to monitor the UV LED temperature in real time. Using the Latest UV LED Technology, the OmniCure® LX400+ accelerates assembly manufacturing processes and saves costs on energy consumption.

Click on Tabs below for Additional Product Information:

Features & Benefits

Features |

Benefits |

| NEW Sequential Exposure of Channels 1, 2, 3, and 4 with the New Channel Configuration Mode FP6 | Customized multi-phase curing processes directly from the LX400+ controller, without using an external control unit. |

Uses the Latest UV LED Technology for Maximum Irradiance at Different Wavelengths:

|

Reduction in UV assembly manufacturing costs with faster curing time and higher power efficiency while supporting a wide range of UV cured adhesives. |

| Precisely controls the UV Light Exposure Time (+/- 0.1 second) and Intensity Level (+/- 1%) of up to four Different UV LED Heads | Consistent repeatability in UV curing assembly manufacturing processes for highest product quality. |

| Highly Efficient and Intelligent UV LED Heads with Extra Cooling Capability and patented Intelli-Lamp® Technology | Maximum UV LED head power efficiency, long term reliability and guaranteed lifetime. |

| High Energy Efficiency from using the latest LED Technology | Approximately 75% less energy consumption than a typical UV arc lamp curing system. |

| Controls up to 4 UV LED Heads simultaneously or independently using a single controller | Versatility in production setup for running up to 4 UV curing heads simultaneously or independently. |

| NEW LED Head Temperature on Display | Optimum efficiency in UV curing manufacturing processes while extending UV LED head lifetime. |

| Autonomous and Robust UV Curing System with Compact Dimensions | Highest performance in dense and harsh manufacturing environments; no additional cooling required. |

| Certifications & Safety Standards | Compliance with CE and RoHS requirements. |

| User-friendly front panel control | Ease of use for quick system set-up in a matter of minutes. |

Specifications

User Interface Description |

|

| Interchangeable UV LED Heads | 1 to 4 individual heads |

| LED Indicators | Indicates Timer Control, Level, Trigger Mode and Emission (UV ON) |

| Mode Control | Mode and Up/Down buttons to control the display mode |

| Timer | Programmable trigger mode:

|

| Level | 15%-100% (with 1% increments) |

| Start/Stop | Control start or stop of the LED emission |

| Key Switch | Turn on/off controller |

| Flashing Alarm | Over temperature protection and lamp-off alarm for LED Heads |

| Foot Pedal | Control start or stop of the LED Emission |

| Controller Dimensions | W x L x H : 7.55” (191.77mm) x 6.6” (167.64mm) x 2.9” (73.66mm) |

External PLC Control Description |

|

| Method | PLC (See the manual for more details) |

| External Input | Start/Stop, intensity level selection, lock out front panel interface and timer mode selection |

| External Output | Emission alarm |

Operating Conditions |

|

| Operating Voltage | Controller Supply Input: 12 VDC Input to AC adaptor: 100-120VAC or 200-240VAC (+/-10%) & 50/60Hz. |

| Power Consumption | 72W max at 120VAC 104W max at 240VAC (with 4 UV LED heads in operation) |

| Ambient Temperature/ Humidity Range | 5° to 35°C, 85% max. (no condensation) |

| Storage Temperature/ Humidity Range | -10° to 60°C, 85% max. (no condensation) |

| Certifications & Safety Standards | RoHS compliant and meets CE requirements |

| Warranty | 1 year |

LX400 vs LX400+

OmniCure® LX400 vs LX400+ Advanced UV LED Spot Curing Systems |

|

| OmniCure® LX400+ system includes three new functions compared to the previous LX400 version: | |

| NEW UV LED Head Temperature on Display | Displays UV LED head temperature during and between UV light exposures in real time. This results in optimum efficiency in UV curing manufacturing processes while extending UV LED head lifetime. |

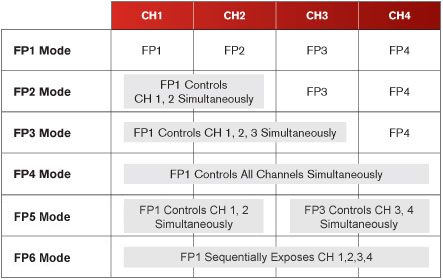

| NEWTwo Additional Foot Pedal Channel Control Configurations: FP5 and FP6 | Channels 1 & 2 vs 3 & 4 simultaneously In FP5 mode, foot pedal #1 controls channels 1 and 2 simultaneously and foot pedal #3 controls channels 3 and 4 simultaneously (see the Foot Pedal Channel Control Table below). Sequential Exposure of Channels 1, 2, 3, and 4 In FP6 mode, foot pedal #1 sequentially exposes channels 1, 2, 3, and 4. This channel control configuration mode allows for customized multi-phase curing processes directly from the LX400+ controller, eliminating the need to use an external control unit to implement multi-phase curing processes. |

Foot Pedal Channel Control |

|

Intelli-Lamp

Patented Intelli-Lamp® Technology |

|

| Pre-Aligned & Focused | Snap-in insertion automatically senses the Intelli-Lamp®, eliminating the need for operator alignment or focusing. |

| Automatic Lamp Hour Tracking | The Intelli-Lamp® technology automatically maintains the lamp hours directly on the lamp to facilitate activation of lamp warranty if required. |

| Broad Spectral Output | The Intelli-Lamp® provides output across virtually the entire visible and UV spectrum, making it suitable for a wide range of adhesive/substrate bonding applications. |

| Built-In Reflector | Each Intelli-Lamp® includes its own new reflector, eliminating the need for reflector replacement. |

| Hot-Strike Prevention | Automatic lamp striking cools and prevents hot-striking to protect lamp life. |

Search in Shop

Recently viewed:

-

OmniCure LX400+

Notice: Undefined property: stdClass::$prices in /home/alphauvc/public_html/templates/rt_nuance/html/mod_virtuemart_product/default.php on line 115

Call for price

Notice: Undefined property: stdClass::$prices in /home/alphauvc/public_html/templates/rt_nuance/html/mod_virtuemart_product/default.php on line 83

© Alpha UV Systems 2016. All rights reserved. Site by Metro Web Design